Based on figures provided by the European Automobile Manufacturers Association (ACEA) More than 6.4 million trucks carrying freight travel through EU highways (7.2 million when trucks exceeding 3.5 tons are from in the United Kingdom are also taken into consideration) transporting millions of tonnes of products that require a complicated control. In the case of vegetables and fruits in particular, Spain exported a total of 11.3 million tonnes in 2023. They are food items that can be perishable, and anything that takes more time to transit is the added challenge.

“It was actually my own experience being a fruit and vegetable exporter from Almeria that inspired me to develop an application that would speed communications between logistics companies as well as their clients, as well as to make it simpler for exporters to know what their merchandise is in anytime,” says Juanjo Barrionuevo. “This is the way that Orus Logistics was born.” Orus Logistics platform, which was started in September 2024 was developed.”

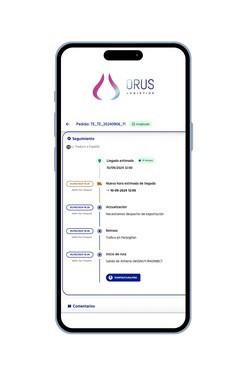

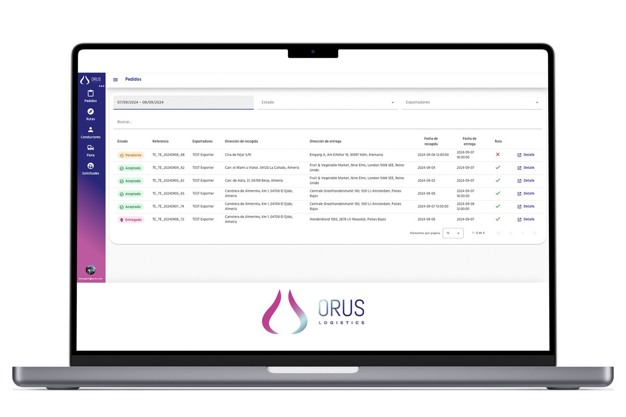

“With this program, exporters as well as their clients can keep track of where their products are, and be able to make a precise prediction of the time they’ll arrive at the destination, with no needing to wait for lengthy conversations with transportation companies in order to know the state of their cargo. “

“Real-time data on location will assist businesses save time, money and money. This will allow companies to provide better service to customers through streamlined communications not just in situations when goods are transported by a single client as well as in instances of groupage where the difficulty of reporting events grows.

Orus Logistics is a global platform for tracking all kind of product on land transportation, and can be accessed in four different the four languages of Spanish, English, French and German. “Any transport business can access this platform via an app, and will be able to offer the service to their customers who will receive it totally free.”

“The application is efficient and user-friendly for logistics firms as well as clients. There is versions designed for PC as well as a mobile version that lets you monitor the state of the situation and where you are or get notified of incidents from anywhere from any device.

“Our purpose for Orus Logistics is to streamline communications and help companies make the most of their time and resource as well as provide exporters with security as well as openness with their customers. Our goal is always to offer the most efficient solutions. Therefore, we’ll remain in touch with users for feedback on their experience, and to listen to their ideas, and we will implement whatever tools are needed for the platform to be 100 percent efficient,” says Juanjo. “As everyone knows that time is money which is why with Orus Logistics we want to aid in managing that as efficiently as we can.”

“Our purpose for Orus Logistics is to streamline communications and help companies make the most of their time and resource as well as provide exporters with security as well as openness with their customers. Our goal is always to offer the most efficient solutions. Therefore, we’ll remain in touch with users for feedback on their experience, and to listen to their ideas, and we will implement whatever tools are needed for the platform to be 100 percent efficient,” says Juanjo. “As everyone knows that time is money which is why with Orus Logistics we want to aid in managing that as efficiently as we can.”

For additional information, click here:

For additional information, click here:

Orus Logistics

Tel. : +34 629 819 035

[email protected]

www.oruslogistics.es