With the northern hemisphere entering the harvest season, pineapples, mangos, and melons are consumed in large quantities. The Japanese peeler innovator Astra is once again busy preparing shipments for retail chains and small-scale factories that require fruit peeling. This month, the company introduced the new generation of peelers, the “KA-750PM,” to its worldwide customers.

[embedded content]

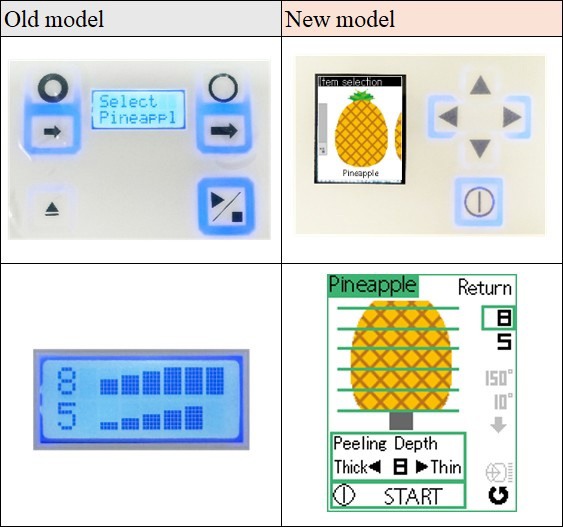

Color LCD screen for easy usage Ryo Takeshita, the sales manager at Astra, shared this recent development, “this model maintains the same peeling performance. The biggest change is the new color display. The old model only showed peeling depth and spin speed with two numbers, but now the display provides much more information, including short animations that demonstrate how to insert fruit and how different settings affect peeling quality. This makes the machine much easier to understand, reducing the chance of incorrect usage.”

“We also updated the durability of the machine. The new model is more robust,” Ryo explains. “In the past, some machines were damaged during shipping because they were compact and handled roughly. We’ve now used stronger materials to prevent damage during transportation. Additionally, we addressed issues with fruit juice entering the machine under extreme conditions, such as high humidity and heavy pressure.

“Finally, although it was a bit of a challenge for us at Astra, we’ve developed a pineapple coring attachment. It’s easy to use, and right after peeling, the core can be removed quickly and smoothly.”

“We aim to help retailers boost their sales” “As a peeler innovator, we aim to help retailers increase the productivity of peeling while saving on labor costs. Of course, we also want to help retailers improve their productivity and boost their sales by presenting beautifully peeled fruits to consumers.”

“Take pineapple as an example. Pineapples are not easy to peel by hand. For convenience, some customers prefer to buy pre-cut ones, regardless of the high price. Ready-to-eat cut pineapples sold in supermarkets are often processed in factories and then shipped to retail stores. But pre-peeled pineapple is quite perishable when kept on the shelf for a longer time

or when the surrounding temperature changes during processing or transport. The quality of the fruit deteriorates, and the fruits easily rot. This not only results in food waste at the store but may also lead to consumer complaints,” Ryo introduced. “Now some stores place the peeler next to the pineapple sales shelf. Customers can have the fruit peeled in-store. The quick peeling performance and beautifully peeled fruit have attracted many customers. It seems that our peeler is also being used as a promotional tool for fruit sales,” Ryo laughs.

“One major update each year” Non-stop innovation is the key to Astra’s business. Using Ryo’s words, “Innovation itself is not about time; it’s about how deeply you think about it.”

“We try to think along with the market and continuously update our machines for better user experiences. For the KA-750 series, we made four major improvements within four years. The peeling yield rates increased by 2%, the blade usage period for the peeler was extended, the weight of the machine became 10 kg lighter, and now it is equipped with a color LCD screen,” Ryo said. “We hope these innovations lead to a shortened return-on-investment for clients, help them reduce waste, increase their productivity, and boost their sales.”

Besides KA-750 series for peeling large fruits such as pineapples, melons and mangos, Astra has varies models such as KA-700H/ FAP-1001 series for peeling small fruits such as apples, oranges, kiwis and more.

For more information:

Mr Ryo Takeshita

ASTRA Inc.

Tel: +81 0245412444

Email: [email protected]

https://peel-a-ton.com/